1.Product Categories:

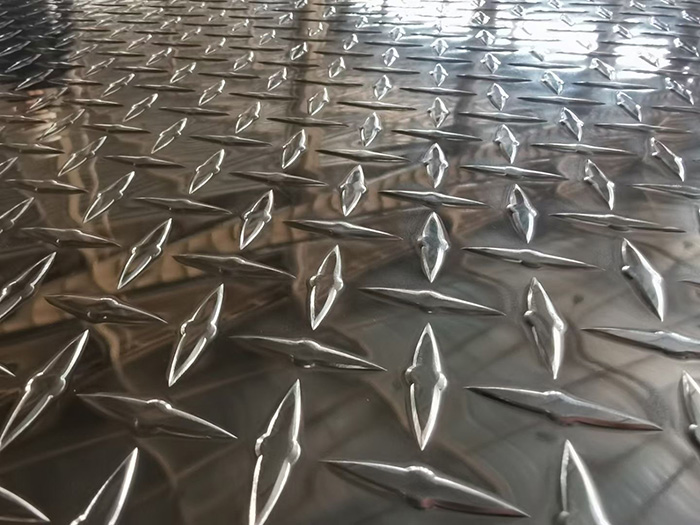

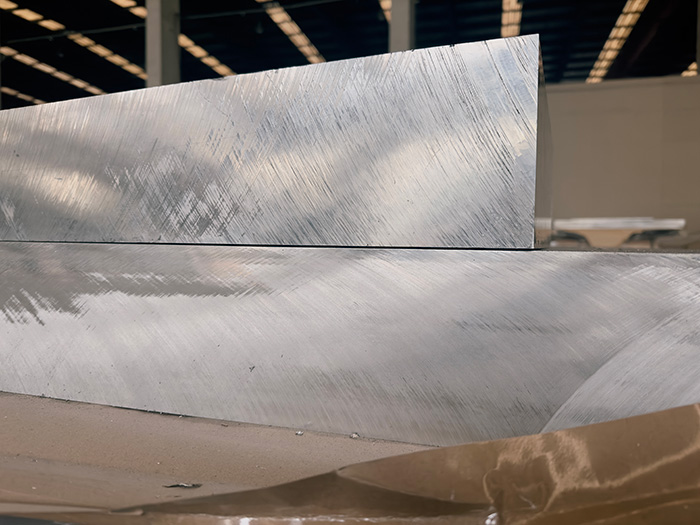

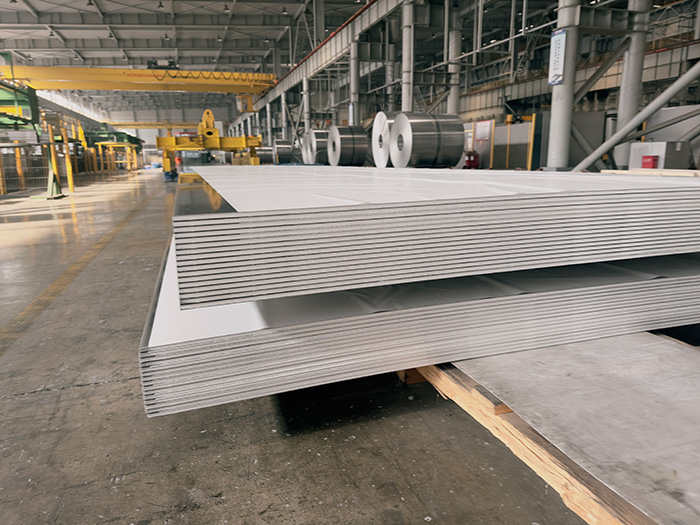

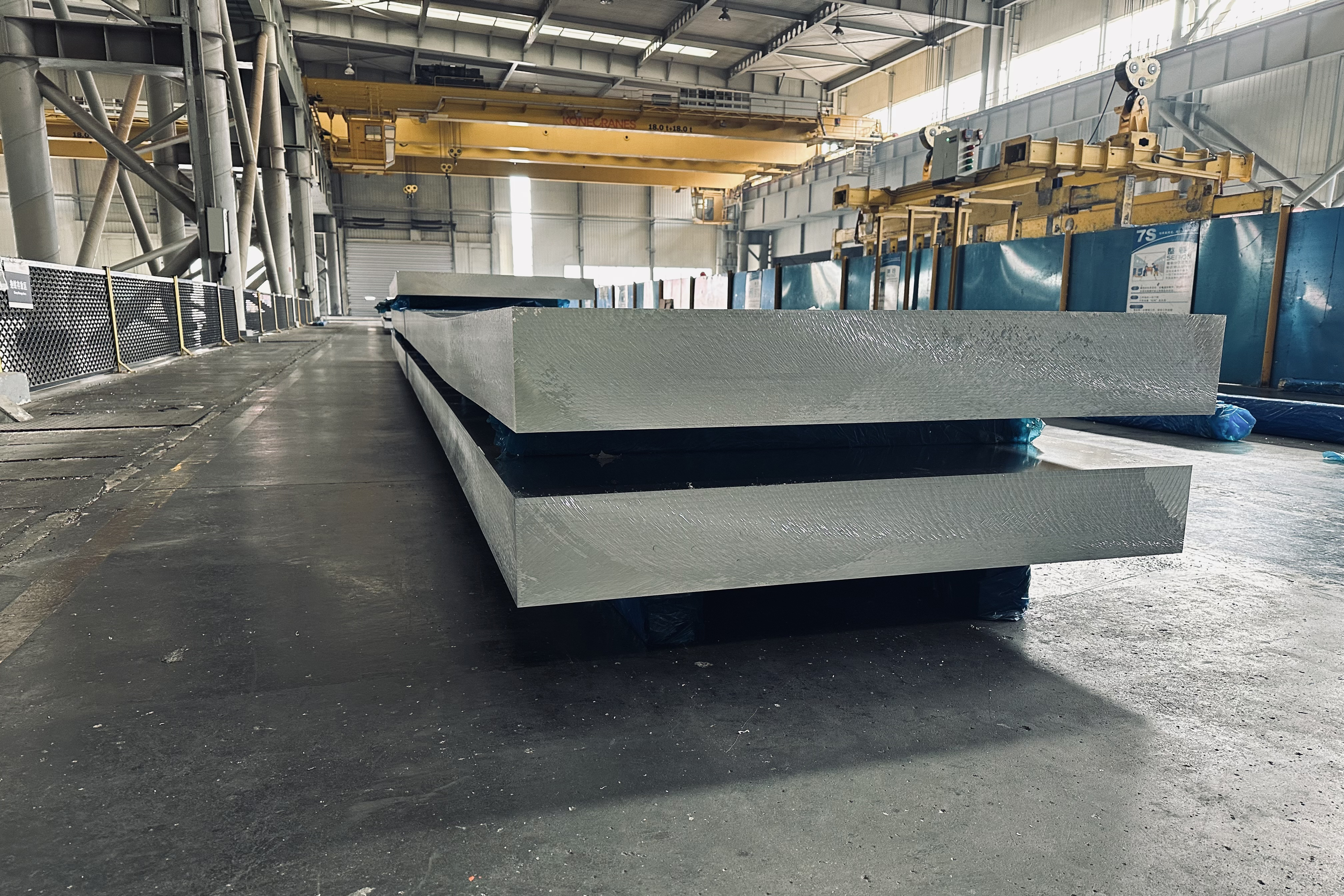

1)Plate: a flat material, either hot or cold rolled, over 6 mm thickness.

2)Middle plate: a flat material, either hot or cold rolled, between 4 & 6 mm thickness.

3)Sheet: a flat, cold rolled material, over 0.2mm but not exceeding 4mm (6mm) in thickness

2.Properties of aluminum plate

1)Light weight, good rigidity, high strength 3.0mm thick aluminum plate weighs 8kg per square plate. To a certain extent to ensure that the aluminum curtain wall panel flat, wind pressure resistance, impact resistance, useful to reduce the load of the building.

2)Aluminum veneer in the weather resistance, self-cleaning and UV resistance, acid and alkali resistance and other aspects are very good, can be more effective against acid rain, outdoor air pollution, UV corrosion. Aluminum veneer is composed of a special molecular layout, dust will not easily fall on it, with excellent self-cleaning function.

3)Replastic function is better. The aluminum plate can be processed into plane, arc, sphere and other complex geometric shapes by using the process of first processing and then painting.

4)Uniform coating, color variety, can choose a relatively wide scale, rich and visual effect is better, the role of decoration is also very good. Advanced electrostatic spraying technology makes the paint and aluminum plate adhesion uniform, color variety, large choice space.

5)Convenient and quick installation and construction. Aluminum plate in the factory molding, construction site does not need to cut, fixed on the skeleton can be.

6)The finish coating of aluminum veneer is selected to be the gloss of the matte type coating, which not only maintains the international popular bright style personality but also deals with the light pollution of the glass curtain wall. It is a rare recycling and green commodity. At the same time, aluminum materials can also be recycled, beneficial to environmental protection.

7)The flame retardant function is better, and it meets the demand in fire protection. The aluminum veneer is composed of high-strength aluminum alloy and fluorocarbon paint or panel, which has outstanding flame retardant and can pass the fire control test.

3.Product Application:

1)Aircraft: Structural members, cladding and many fitments.

2)Aerospace: Satellites, space laboratory structures and cladding.

3)Marine: Superstructures, hulls, interior fitments.

4)Rail: Structures, coach panelling, tankers and freight wagons.

5)Road: Car chassis & body panels, Buses, truck bodies, tippers, tankers, radiators, trim, traffc signs and lighting columns.

6)Building: Insulation, roof, cladding and guttering.

7)Engineering: Welded structures, tooling plate,cladding and panelling, and heat exchangers.

8)Electrical: Transformer windings, busbars, cable sheathing, and switchgear.

9)Chemical: Process plant, vessels and chemical carriers.

10)Food: Handling and processing equipment, and hollowware.

11)Packaging: Cans, bottle caps, beer barrels, wrapping, packs and containers for a wide range of food and non-food products.

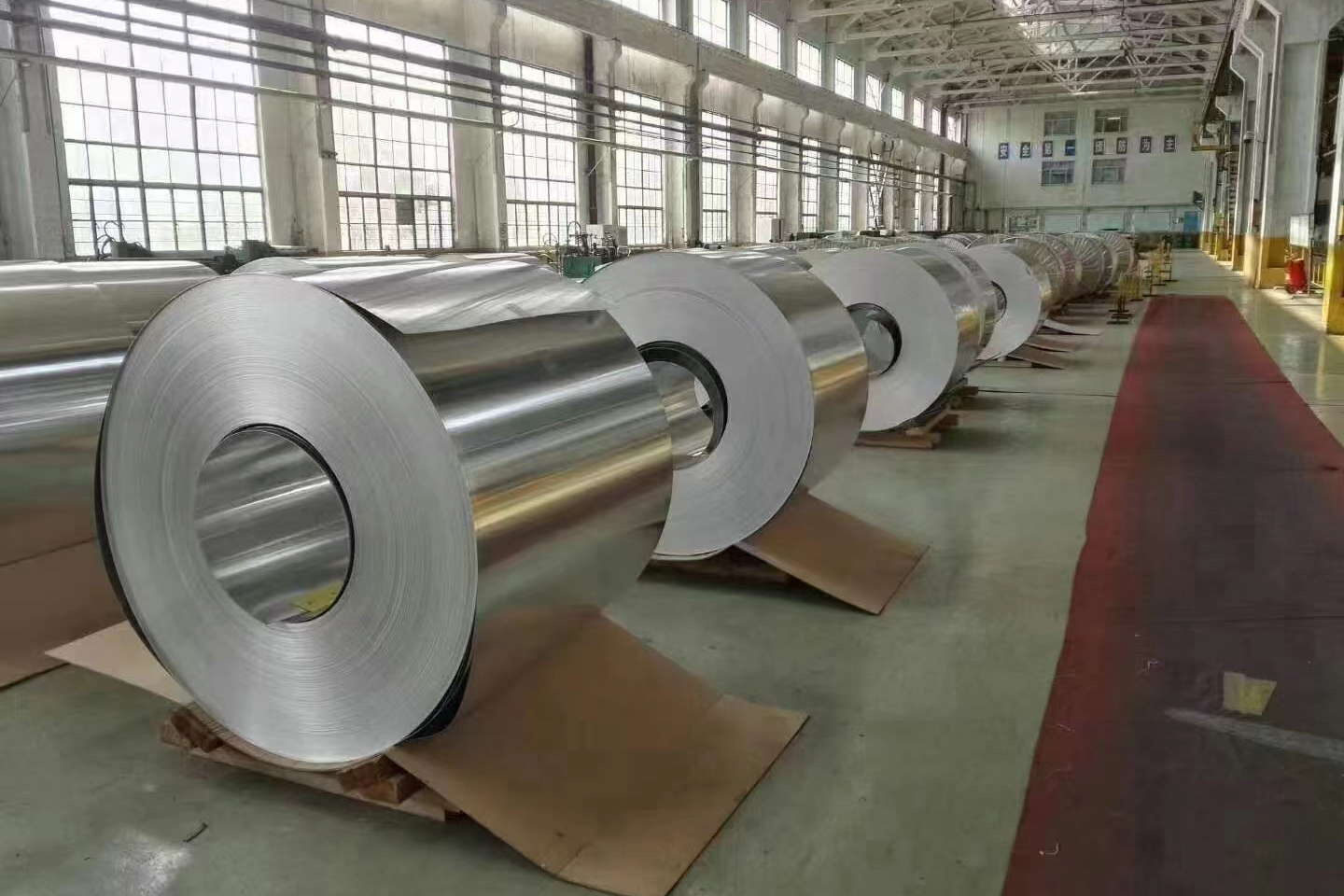

1.Product Categories Introduction:

Coil: Called strip, generally no more than 3mm thick. A coil of aluminum may go through various processing steps once it arrives at a metalworking facility. For example, aluminum coils can be cut, welded, bent, stamped, engraved, and affixed to other metal items. Aluminum suppliers provide aluminum coils to production facilities, metal fabricators, and other metalworking operations requiring this metal to produce so many of the objects our world has come to rely on ranging from auto parts to the cans we rely on to protect and store food and countless other items.

2.Common standards and characteristics of aluminum coils:

It is a metal product for flying shear after rolling and bending in aluminum coil casting mill. Aluminum skin with good appearance and gloss is commonly used in pipeline construction, rock wool, glass wool, aluminum silicate, and external skin construction of pipeline insulation. Aluminum coil is widely used in electronics, packaging, construction and machinery.

1)Low density: The density of aluminum and aluminum alloys is close to 2.7g/, which is about 1/3 of that of iron or copper.

2)High strength: Aluminum and aluminum alloys have high strength. The strength of matrix can be strengthened by cold working, and some grades of aluminum alloy can also be strengthened by heat treatment.

3)Good electrical and thermal conductivity. The electrical and thermal conductivity of aluminum is second only to that of silver, copper and gold.

4)Protective film: By artificial anodizing and coloring, cast aluminum alloy with good casting performance or deformed aluminum alloy with good processing plasticity can be obtained.

5)Processing: After adding alloy elements, cast aluminum alloy with good casting performance or deformed aluminum alloy with good processing plasticity can be obtained.

3.Product Application:

1. Color coated aluminum coil, aluminum-plastic board, integrated metal insulation board, aluminum veneer, aluminum honeycomb board, aluminum ceiling and sheet.

2. Aluminum metal roof, aluminum corrugated board, built-in aluminum plate, built-out aluminum plate, rolling door, downpipe and decorative strip.

3. Aluminum packaging outside the pipeline, traffic signs, aluminum curtain walls, aluminum cookware, solar panels, etc.

4. Condenser, panel and interior trim panel

1. Product Categories:

Foil: a cold rolled material 0.2mm thick or less

2.Properties of aluminum Foil

1) Mechanical properties: The mechanical properties of aluminum foil mainly include tensile strength, elongation, cracking strength, etc. The mechanical properties of aluminum foil are mainly determined by its thickness.

Aluminum foil is light in weight, good in ductility, thin in thickness and small in mass per unit area. However, it is low in strength, easy to tear, easy to break and produce holes when folded, so it is generally not used for packaging products alone. In many cases, it is compounded with other plastic films and paper to overcome its shortcomings.

2) High barrier: Aluminum foil has high barrier to water, water vapor, light and fragrance, and is not affected by environment and temperature. Therefore, it is often used in fragrance-preserving packaging and moisture-proof packaging to prevent moisture absorption, oxidation and volatile deterioration of the contents of the package. Especially suitable for high-temperature cooking, sterilization and packaging of food.

3) Corrosion resistance: An oxide film is naturally formed on the surface of aluminum foil, and the formation of the oxide film can further prevent the continuation of oxidation. Therefore, when the contents of the package are highly acidic or alkaline, protective coatings or PE are often coated on its surface to improve its corrosion resistance.

4) Heat resistance and low temperature resistance: the aluminum foil is stable at high temperature and low temperature, does not expand and shrink at -73~371℃, and has good thermal conductivity, with a thermal conductivity of 55%. Therefore, it can not only be used for high-temperature cooking or other hot processing, but also for frozen packaging.

5) Shading: Aluminum foil has good shading, its reflective rate can be as high as 95%, and its appearance is silvery white metallic luster. It can show good packaging and decoration effect through surface printing and decoration, so aluminum foil is also a high-grade packaging material.

3.Product Application:

1. Cardboard foil 2. Household foil 3. Pharmaceutical foil 4. Cigarette foil

5. Cable foil 6. Cover foil 7. Power capacitor foil 8. Wine label foil.