You might ask yourself, “What makes aluminum in cars so commonplace?” or “What is it about aluminum that makes it such a great material for car bodies?” without realizing that aluminum has been used in auto manufacturing since the beginning of cars. As early as 1889 aluminum was produced in quantity and cast, rolled, and formed in cars.

Auto manufactures seized the opportunity to work with an easier-to-form material than steel. At the time, only purer forms of aluminum existed, which are characteristically softer and possess great formability and excellent corrosion resistance that holds up over time. These factors led car makers to sand cast and form extensive body panels that were then welded and polished by hand.

By the mid-20th century, some of the most esteemed auto manufacturers were applying aluminum in cars. This includes Bugatti, Ferrari, BMW, Mercedes, and Porsche.

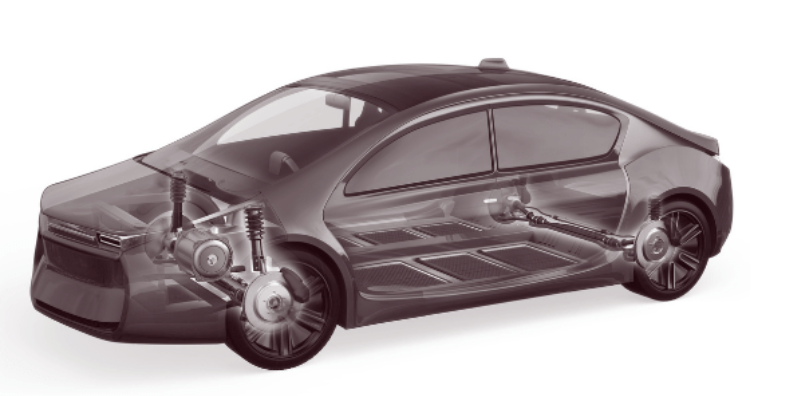

Cars are complex machines consisting of roughly 30,000 parts. Car bodies, or the skeleton of the vehicle, are the most expensive and critical to vehicle manufacturing.

They include the outer panels which provide shape to the vehicle, and the inner panels which act as reinforcement. The panels are welded together to pillars and railing. Car bodies then include front and rear doors, engine beams, wheel arches, bumpers, hoods, passenger compartments, front, roof, and floor paneling.

Structural soundness is the most important requirement for car bodies. However, car bodies must also be lightweight, affordable to produce, resistant to rust, and have the attractive qualities consumers seek, like excellent surface finishing characteristics.

Aluminum satisfies the range of these requirements for a few reasons:

Naturally, aluminum is an exceptionally versatile material. Aluminum’s formability and corrosion resistance make it easy to work with and shape.

It’s also available in various formats, like aluminum sheet, aluminum coil, aluminum plate, aluminum tube, aluminum pipe, aluminum channel, aluminum beam, aluminum bar, and aluminum angle.

Versatility allows for aluminum to be a choice material for a range of auto applications that might require different characteristics, be it size and shape, yield strength, finishing character, or corrosion resistance.

Performance quality and versatility can be enhanced through various fabrication processes, such as bake hardening, work and precipitation hardening, drawing, annealing, casting, molding, and extrusion. Improved welding technologies continue to make joining aluminum easier to perform with safer outcomes.

Aluminum has a high strength-to-weight ratio, meaning it is light and durable. Automotive trends in aluminum have focused on weight reduction in vehicles, a main objective in the industry in order to meet stricter emissions targets.

Research conducted by Drive Aluminum confirms that aluminum in cars reduces vehicle weight and increases fuel economy and range in electric vehicles (EV). Since consumer demand and environmental incentives are leading to increased production of EV, we can expect that aluminum in car bodies will continue to rise as a way to offset the weight of batteries and lower emissions.

That aluminum can be alloyed with a range of elements to amplify qualities like strength, electrical conductivity, and corrosion resistance increases its use in auto manufacturing.

Aluminum is separated into alloy series which are determined by their main alloying elements. The 1xxx, 2xxx, 3xxx, 4xxx, 5xxx, 6xxx, and 7xxx aluminum alloy series all include alloys that are put to use in car bodies.

The 1xxx series of aluminum is the most pure aluminum available. At 99% pure, 1100 aluminum sheet is extremely malleable. It also demonstrates excellent corrosion resistance. This was one of the first alloys used in vehicles and continues to be used today, primarily in heat insulators.

The 2xxx series of aluminum is alloyed with copper. 2024 is often used in the manufacturing of pistons, break components, rotors, cylinders, wheels and gears as it shows high strength and excellent fatigue resistance.

The 3xxx manganese series of aluminum has great formability. You’re most likely to see 3003, 3004 and 3105.

The 4xxx series of aluminum is alloyed with silicon. 4032 will be used for pistons, compressor scrolls, and engine components as it demonstrates excellent weldability and abrasion resistance.

5xxx series is one of the most popular for aluminum car bodies. Its main alloying element is magnesium, known to increase strength.

The 6xxx aluminum series is alloyed with magnesium and silicon, they boast some of the best extrusion and casting capabilities, and demonstrate ideal surface finishing character.

The 7xxx is the most powerful and highest strength alloy class, alloyed with zinc and magnesium.

We have every reason to believe that what auto manufacturers picked up on in the late 1800’s is still true today: aluminum is an outstanding choice for vehicles! Since it was first introduced, alloys and improved fabrication techniques have only increased the use of aluminum in cars. Coupled with global concern about sustainability and environmental impact, aluminum is expected to achieve a considerable range and depth of impact in the automotive industry.

Author: Sara Montijo

Source:https://www.kloecknermetals.com/blog/aluminum-in-cars/

(For infringement, please contact us deleted.)

Edited by May Jiang from MAT Aluminum