Process

Flow

1.Anodizing

of silver-based materials and silver-based electrophoretic materials: Loading -

Water rinsing - Low-temperature polishing - Water rinsing - Water rinsing -

Clamping - Anodizing - Water rinsing - Water rinsing - Water rinsing - Sealing

holes - Water rinsing - Water rinsing - Blanking - Air drying - Inspection -

Entering the electrophoresis process - Packaging.

2.Anodizing

of frosted materials and frosted electrophoretic materials: Loading -

Degreasing - Water rinsing - Acid etching - Water rinsing - Water rinsing -

Alkali etching - Water rinsing - Water rinsing - Neutralization and brightening

- Water rinsing - Water rinsing - Clamping - Anodizing - Water rinsing - Water

rinsing - Water rinsing - Sealing holes - Water rinsing - Water rinsing - Blanking

- Air drying - Inspection - Entering the electrophoresis process - Packaging.

3.Anodizing

of coloring materials and coloring electrophoretic materials: Loading - Water

rinsing - Low-temperature polishing - Water rinsing - Water rinsing - Clamping

- Anodizing - Water rinsing - Water rinsing - Water rinsing - Coloring - Water

rinsing - Water rinsing - Sealing holes - Water rinsing - Water rinsing -

Inspection - Entering the electrophoresis process - Blanking - Air drying -

Inspection - Packaging.

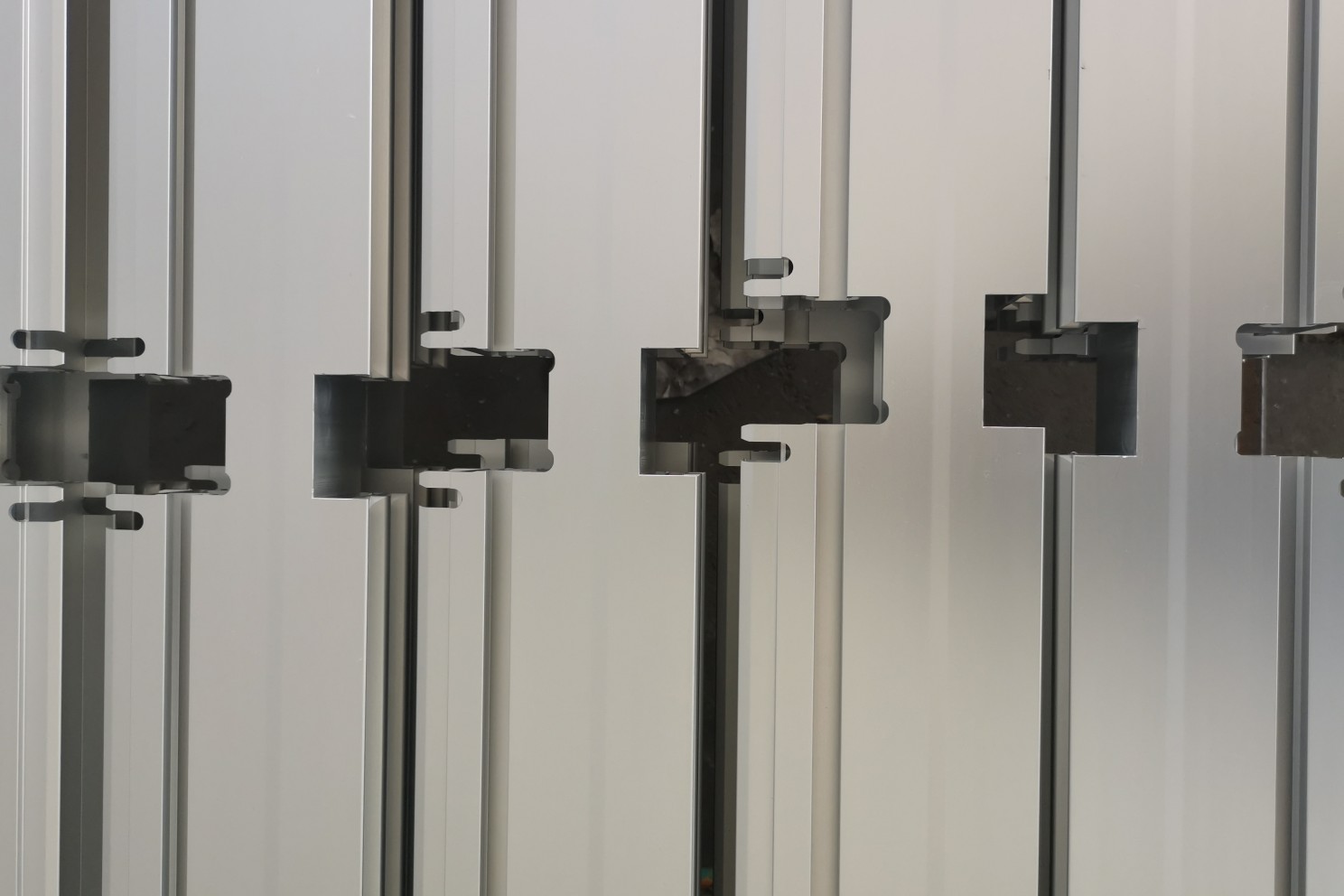

Anodizing products of MAT Aluminum

Material Loading

1.Before

loading the profiles, the contact surfaces of the lifting rods should be

polished clean, and the loading should be done according to the standard

number. The calculation formula is as follows: Number of loaded profiles =

Standard current density x Single profile area.

2.Principles

for considering the number of racks: The utilization rate of the silicon

machine capacity should not exceed 95%; the current density should be set at

1.0-1.2 A/dm; the profile shape should leave necessary gaps between two

profiles.

3.Calculation

of anodizing time: Anodizing time (t) = Film thickness constant K x Current

density k, where K is the electrolysis constant, taken as 0.26-0.32, and t is

in minutes.

4.When

loading the upper racks, the number of profiles should follow the "Profile

Area and Number of Upper Racks" table.

5.To

facilitate liquid and gas drainage, the upper racks should be tilted during

bundling, with an inclination angle of around 5 degrees.

6.The

conductive rod can extend beyond the profile by 10-20mm on both ends, but it

should not exceed 50mm.

Low-temperature Polishing Process

1.The

concentration of low-temperature polishing agent in the tank should be

controlled at a total acid concentration of 25-30 g/l, with a minimum of 15

g/l.

2.The

temperature of the polishing tank should be maintained at 20-30°C, with a

minimum of 20°C. The polishing time should be 90-200 seconds.

3.After

lifting and draining the residual liquid, the profiles should be quickly transferred

to a water tank for rinsing. After two water rinses, they should be promptly

transferred to the anodizing tank. The residence time in the water tank should

not exceed 3 minutes.

4.Before

polishing, the low-temperature polishing materials should not undergo any other

treatment, and other tank liquids should not be introduced into the polishing

tank.

Degreasing Process

1.The

degreasing process is carried out in an acid solution at room temperature, with

a duration of 2-4 minutes and an H2SO4 concentration of 140-160 g/l.

2.After

lifting and draining the residual liquid, the profiles should be placed in a

water tank for rinsing for 1-2 minutes.

Frosting (Acid Etching) Process

1.After

degreasing, the profiles should be rinsed in a water tank before entering the

acid etching tank.

2.Process

parameters: NH4HF4 concentration of 30-35 g/l, temperature of 35-40°C, pH value

of 2.8-3.2, and acid etching time of 3-5 minutes.

3.After

acid etching, the profiles should go through two water rinses before entering

the alkali etching tank.

Alkali Etching Process

1.Process

parameters: Free NaOH concentration of 30-45 g/l, total alkali concentration of

50-60 g/l, alkali etching agent of 5-10 g/l, AL3+ concentration of 0-15 g/l,

temperature of 35-45°C, and alkali etching time for sand materials of 30-60

seconds.

2.After

lifting and draining the solution, the profiles should be quickly transferred

to a water tank for thorough rinsing.

3.The

surface quality should be checked after cleaning to ensure there are no

corrosion marks, impurities, or surface adhesion before entering the

brightening process.

Brightening Process

1.Process

parameters: H2SO4 concentration of 160-220 g/l, HNO3 in appropriate amount or

50-100 g/l, room temperature, and brightening time of 2-4 minutes.

2.After

lifting and draining the residual liquid, the profiles should be quickly

transferred to a water tank for 1-2 minutes, followed by a second water tank

for another 1-2 minutes.

3.After

two rounds of cleaning, the aluminum wire on the racks should be clamped

tightly to ensure good contact during the anodizing process. Ordinary materials

are clamped at one end of the rack's aluminum wire, while coloring materials

and electrophoretic materials are clamped at both ends.

Anodizing Process

1.Process

parameters: H2SO4 concentration of 160-175 g/l, AL3+ concentration ≤20 g/l,

current density of 1-1.5 A/dm, voltage of 12-16V, anodizing tank temperature of

18-22°C. The electrification time is calculated using the formula. anodized

film requirements: silver material 3-4μm, white sand 4-5μm, electrophoresis 7-9μm;

2.The

anode racks should be placed steadily in the conductive seats, and it should be

confirmed that there is no contact between the profiles and the cathode plate

before starting the anodizing process.

3.After

anodizing, the anode rods should be lifted out of the liquid, tilted, and

drained of residual liquid. Then they should be transferred to a water tank for

rinsing for 2 minutes.

4.Non-coloring

profiles can enter the secondary water tank for sealing treatment.

Coloring Process

1.Coloring

products should only be arranged in single-row double-line configurations, with

a distance between products equal to or greater than the corresponding face

width of adjacent products. Generally, when measured by fingers, the distance

should be greater than or equal to the width of two fingers. The bundles must

be tight and secure, and only new lines should be used for bundling.

2.The

anodizing tank temperature during coloring should be controlled at 18-22°C to

ensure uniform and fine anodized film thickness.

3.The

anodized coloring areas in each row should be approximately equal.

4.After

coloring, the profiles should be tilted, compared with a color board, and if

the conditions are met, they can be rinsed in a water tank. Otherwise, specific

measures should be taken.

5.It

is advisable to avoid coloring different types of products or different batches

of products on the same rack.

Anodizing products of MAT Aluminum

Sealing Process

1.Place

the anodized profiles in a sealing tank to close the porous anodized film and

enhance the corrosion resistance of the anodized film.

2.Process

parameters: Normal sealing temperature of 10-30°C, sealing time of 3-10

minutes, pH value of 5.5-6.5, sealing agent concentration of 5-8 g/l, nickel

ion concentration of 0.8-1.3 g/l, and fluoride ion concentration of 0.35-0.8

g/l.

3.After

sealing, lift the racks, tilt and drain the sealing liquid, transfer them to a

water tank for a second rinse (1 minute each time), blow dry the profiles,

remove them from the racks, inspect and dry them before packaging.

Edited

by May Jiang from MAT Aluminum