Introduction

With the development of the automotive industry, the market for aluminum alloy impact beams is also growing rapidly, albeit still relatively small in overall size. According to the forecast by the Automotive Lightweight Technology Innovation Alliance for the Chinese aluminum alloy impact beam market, by 2025, the market demand is estimated to be around 140,000 tons, with a market size expected to reach 4.8 billion RMB. By 2030, the market demand is projected to be approximately 220,000 tons, with an estimated market size of 7.7 billion RMB, and a compound annual growth rate of about 13%. The development trend of lightweighting and the rapid growth of mid-to-high-end vehicle models are important driving factors for the development of aluminum alloy impact beams in China. The market prospects for automotive impact beam crash boxes are promising.

As costs decrease and technology advances, aluminum alloy front impact beams and crash boxes are gradually becoming more widespread. Currently, they are used in mid-to-high-end vehicle models such as Audi A3, Audi A4L, BMW 3 series, BMW X1, Mercedes-Benz C260, Honda CR-V, Toyota RAV4, Buick Regal, and Buick LaCrosse.

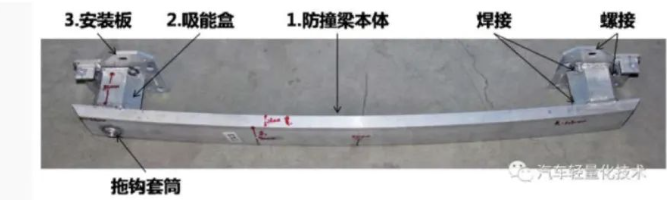

Aluminum alloy impact beams are mainly composed of impact crossbeams, crash boxes, mounting baseplates, and towing hook sleeves, as shown in Figure 1.

Figure 1: Aluminum Alloy Impact Beam Assembly

The crash box is a metal box located between the impact beam and two longitudinal beams of the vehicle, essentially serving as an energy-absorbing container. This energy refers to the force of impact. When a vehicle experiences a collision, the impact beam has a certain degree of energy-absorbing capability. However, if the energy exceeds the capacity of the impact beam, it will transfer the energy to the crash box. The crash box absorbs all of the impact force and deforms itself, ensuring that the longitudinal beams remain undamaged.

1 Product Requirements

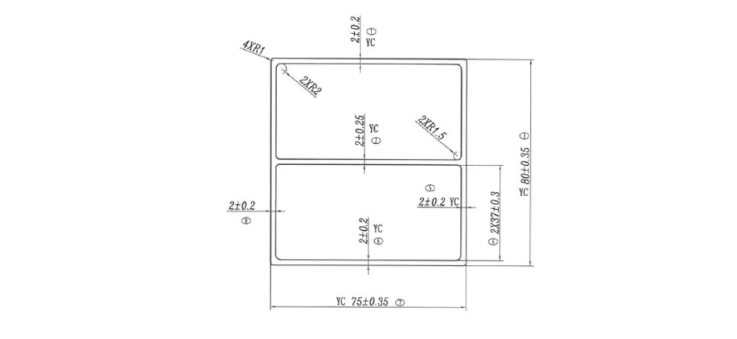

1.1 Dimensions must adhere to the drawing’s tolerance requirements, as shown in Figure 2.