A Revolutionary Breakthrough in the Aluminum Processing Industry: The Innovation and Application Value of MQP Super Grain Refiners

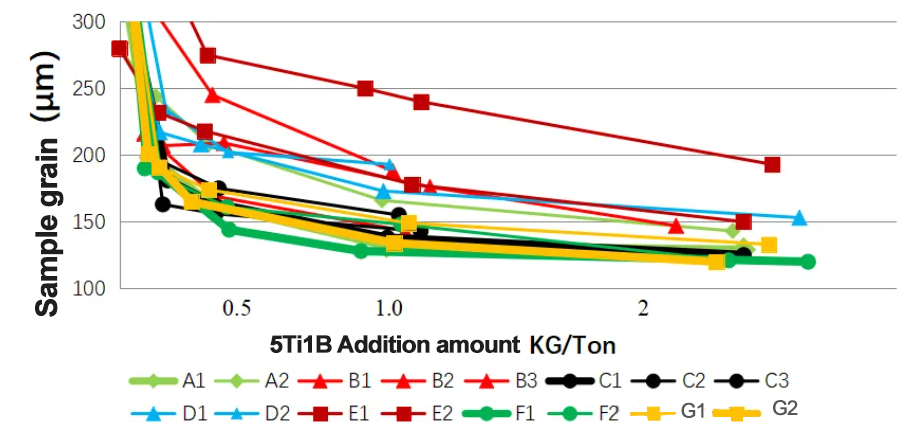

A Revolutionary Breakthrough in the Aluminum Processing Industry: The Innovation and Application Value of MQP Super Grain RefinersIn the evolution of the aluminum processing industry, grain refinement technology has consistently played a central role in determining product quality and production efficiency. Since the establishme......

2025-07-26 Process Characteristics and Application Analysis of Direct and Indirect Extrusion for Aluminum Alloys

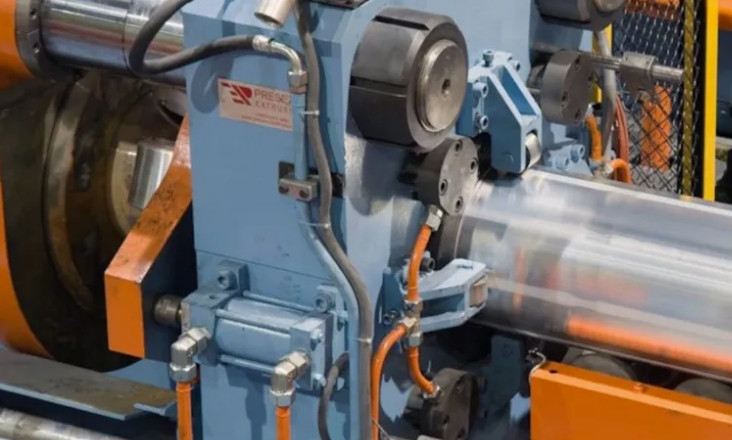

Process Characteristics and Application Analysis of Direct and Indirect Extrusion for Aluminum AlloysAlthough virtually all aluminum alloys are extrudable in theory, evaluating the extrudability of a specific part requires a comprehensive consideration of factors such as dimensions, geometry, alloy t......

2025-07-16